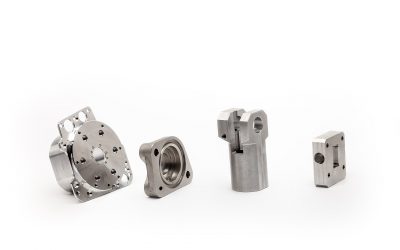

MetMax Europe’s machining centres range from traditional, universal equipment to state-of-the-art numerically controlled (CNC) three, four or five-axis machining centres with horizontal and vertical structures. MetMax Europe typically develops machining, device and tool technology for mass-produced parts based on its own internal competencies.

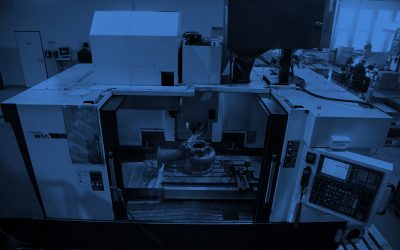

The backbone of the technological base is formed by four-axis, twin-palette machines with a palette size of 500 mm.

This technology is characterised by high productivity, versatility and the minimisation of downtime.

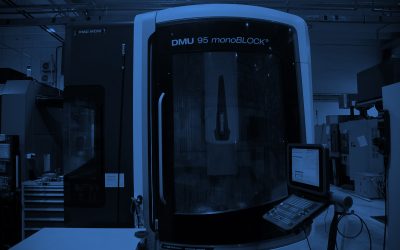

MetMax Europe’s five-axis machining centres have palette sizes of 300 and 1200 mm (in some cases with an additional lathe function) that satisfy diverse machining needs.

The three-axis, vertical machining centres (even with a table size of more than 1000 mm) primarily support the cost-efficient manufacture of larger workpieces and/or simpler workpieces.

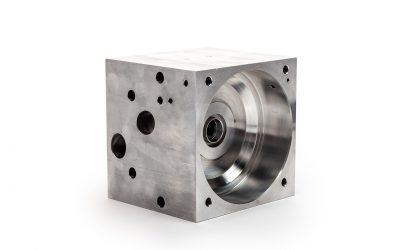

Maximum range of dimensions: 650x850x950 mm

Typical and maximum accuracy: depending on geometry and material quality, it is typically under 0.01 mm, maximum accuracy: as much as 0.005 mm.

Our main machine manufacturer supply partners: DMG Mori, Okuma, Enshu, Toyoda, Doosan