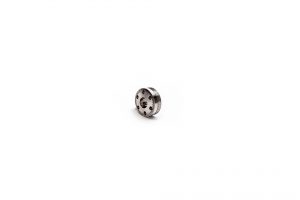

The majority of our components require high-accuracy and complex turning, milling and grinding technologies, typically with a tolerance of 0.01–0.02 mm, or as much as 0.005 mm.

In the past decades, MetMax Europe obtained extensive experience in the machining of moulds, stainless steel and traditional steel, aluminium, copper, bronze and certain special materials (such as Alloy, POM).

Annealing and induction hardening of our components are carried out with our own technology, and our certified material laboratory is suitable for measuring the hardness of heat-treated parts and for crack detection. With the support of our extensive supplier network, we are able to fulfil most induction hardening and surface treatment requirements.

MetMax Europe produces more than 4000 parts and has several decades of experience in the industrial sector in the following fields: